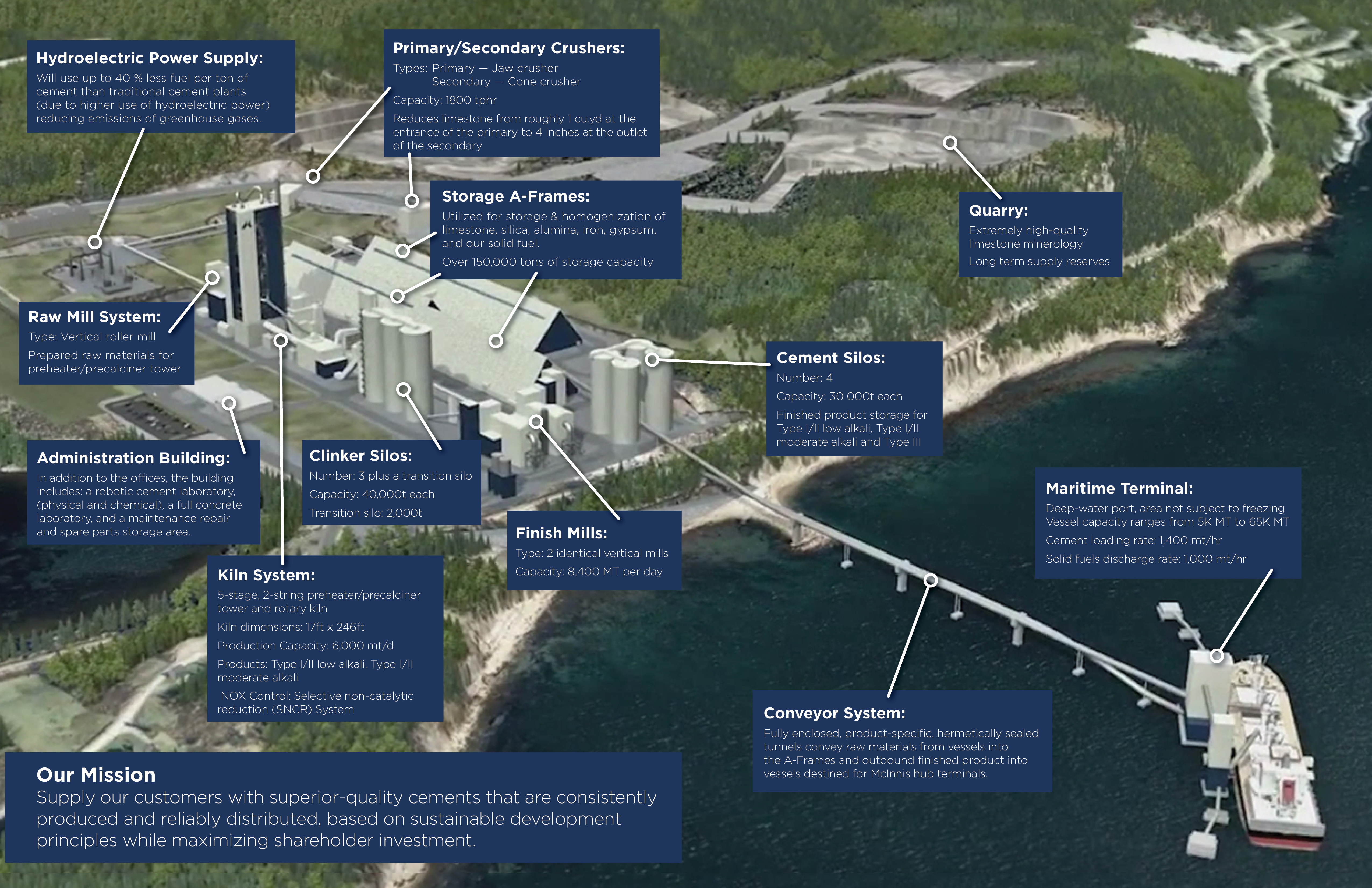

The Plant

The McInnis Cement plant in Port-Daniel–Gascons is a major industrial complex in Canada. More than $1 billion was invested in the plant and network of terminals.

Our plant is a model of environmental performance and meets or exceeds the highest standards in the world.

The site of the Port-Daniel–Gascons cement plant has many features that give it key advantages. Adjacent to the plant is a quarry that contains extremely high quality limestone. The deep-water marine terminal dramatically reduces transportation costs, making shipping both cost-effective and highly competitive. Furthermore, access to maritime transport means a substantial reduction in the ecological footprint generally associated with cement transportation. In fact, just one ship can carry the equivalent of 1,500 truckloads of cement.

The plant has obtained ISO 9001, 14001 and NSF certifications.

With these unique features, this project is an economic driver for the Gaspé region – and in larger part, the entire province of Quebec. The plant provides a reliable source of consistently high-quality cements to North America’s eastern seaboard, served by a network of strategically located modern terminals and equipped with customer support in all McInnis markets.

Click here to see the latest progress video from construction to operation.

Click image below to view plant layout and components.

The Product

The Port-Daniel – Gascons, QC plant produces three types of cement: an ASTM Type I/II Low Alkali Cement (GU-LA as per CSA), an ASTM Type I/II Moderate Alkali (GU as per CSA) and an ASTM Type III High Early (HE as per CSA).

The mineralogy of the on-site limestone quarry contains the perfect balance of ingredients to produce a high-performing Portland cement. The Cement and Concrete Reference Laboratory (CCRL) has inspected our cement laboratory, which is able to make real-time adjustments and ensure that the high performance products are kept within tight tolerances. Coupled with the natural blending that occurs as the product moves through our distribution system, McInnis Portland cements are among the most consistent in the industry.

An integrated concrete testing laboratory is incorporated into our continuous loop feedback system maintaining our focus on key characteristics of cement performance in concrete: early strength gain, appropriate set times, water demand consistency and admixture compatibility. Our Quality Assurance program is designed around ISO 9001-2015 principles, policies and protocols.

The Distribution Network

The McInnis distribution network begins with the customer in mind evidenced by design elements. Reliability of supply with convenient pick-up locations and customer-friendly delivery options is critical to any supply chain.

Supply safeguards begin at the plant where 120,000 mt of finished product storage capacity resides. Vessels ranging from 5,000 mt to 35,000 mt transport cement from the plant to main distribution hubs along the coast. Those hubs, with storage capacities of up to 40,000 mt will provide ample supply to local metropolitan markets. A series of rail-served, satellite terminals provide efficient pick-up access for inland customers.

McInnis has developed its terminal network to serve markets in the northeastern part of North America.

Click the image below to view a larger map.

The McInnis Approach

The McInnis approach to the market is customer-centered and value based. We focus on superior execution on the areas our customers find most critical.

Product Performance and Consistency:

With our high quality limestone, modern production and quality assurance technologies and our commitment to excellence, McInnis offers products that exceed industry benchmarks for performance in concrete. Our in-house concrete laboratory routinely measures our performance across a variety of mix designs to ensure superiority.

Our robust Quality Assurance Program coupled with in-line monitoring technology and a cement laboratory enabling real-time adjustments deliver best-in-class product consistency through the supply chain. When your mix designs are dialed-in you can be assured that our cement will maintain its performance.

Product Availability:

Our properly resourced supply chain with safeguards throughout and superior inventory allowance factors enables McInnis to be sufficiently sized to handle your business volumes today and in the future.

McInnis has strategically positioned hub and satellite terminals that are efficient, accessible, safe and clean. Our self-service loading facilities provide the industry’s most convenient loading times or round-the-clock access to product.

Customer Service:

Our full-service Customer Care Center staffed, trained, motivated and resourced handles all customer inquiries from initiation to completion.

When qualifying our products for complex projects or optimizing mixes for your product performance is required you can count on our field-based Technical Services Specialists to be available and knowledgeable on industry applications and regional materials and standards.

Our team of professional experienced Territory Managers, supported by engaged management, is focused on exceeding your expectations and providing value-based services aimed at supporting the growth of your enterprise. We will be proactive listeners ready to assist you in meeting challenges that develop in the marketplace. We recognize that your success and our performance are intrinsically connected.

Competitive Offer:

McInnis is positioned to be able to be competitive long-term as a result of quarry quality and reserves, hydroelectric power, modern production and distribution facilities, efficient water-based in-bound and out-bound material moves and right-sized terminal and plant inventory capacities. Partnering with McInnis means you are aligning with a supplier with commitment and staying power.

Integrity:

All the above elements are built upon behaviors of honesty, ethics, respect, accountability and fairness and are embraced by all team members. These attributes form the foundation of our relationships with suppliers, customers and the community.