Material Storage & Conveying

The seasonality of cement demand can be difficult to manage for the production team at most cement plants. In the winter months when demand slackens, there can be inventory capacity issues. Conversely in the peak construction season, demand can outstrip supply, making the inventory built-up over the winter critical.

At Port-Daniel – Gascons those challenges have been taken into consideration and investments have been made to smooth those peaks and valleys. There are three 40,000 mt clinker silos for Type I/II moderate alkali and Type I/II low alkali for a total of 120,000 mt of clinker storage. For finished products there are four 30,000 mt silos also providing 120,000 mt of cement storage. That feature, combined with our ship, rail, hub and satellite terminal inventories ensuring McInnis’ customers ample product during peak periods.

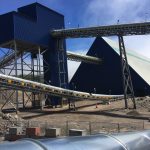

The unique A-Frame storage area protects our raw materials from the elements and offers mechanical elements to increase the homogenization of the raw material feed. In their entirety, the A-Frames can hold approximately 160,000 mt of materials. Current plans call for six different materials; limestone, silica, alumina, iron, gypsum and fuel.